Description

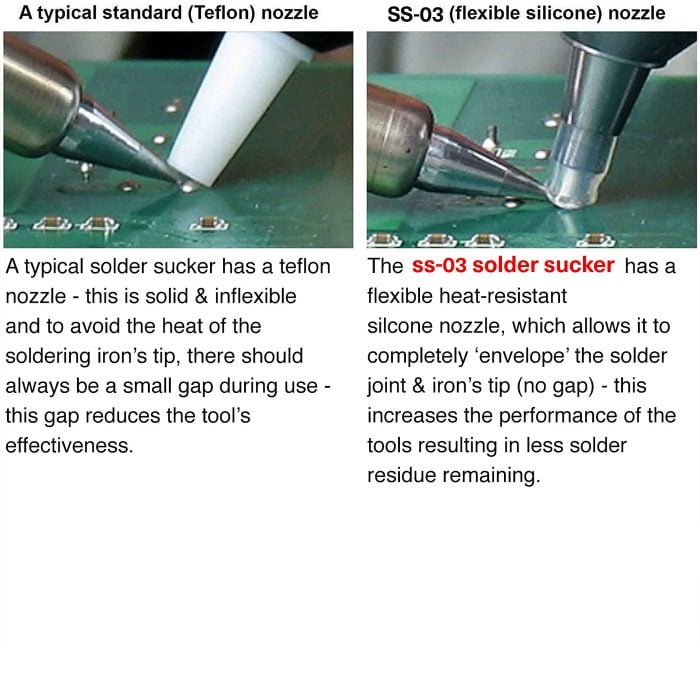

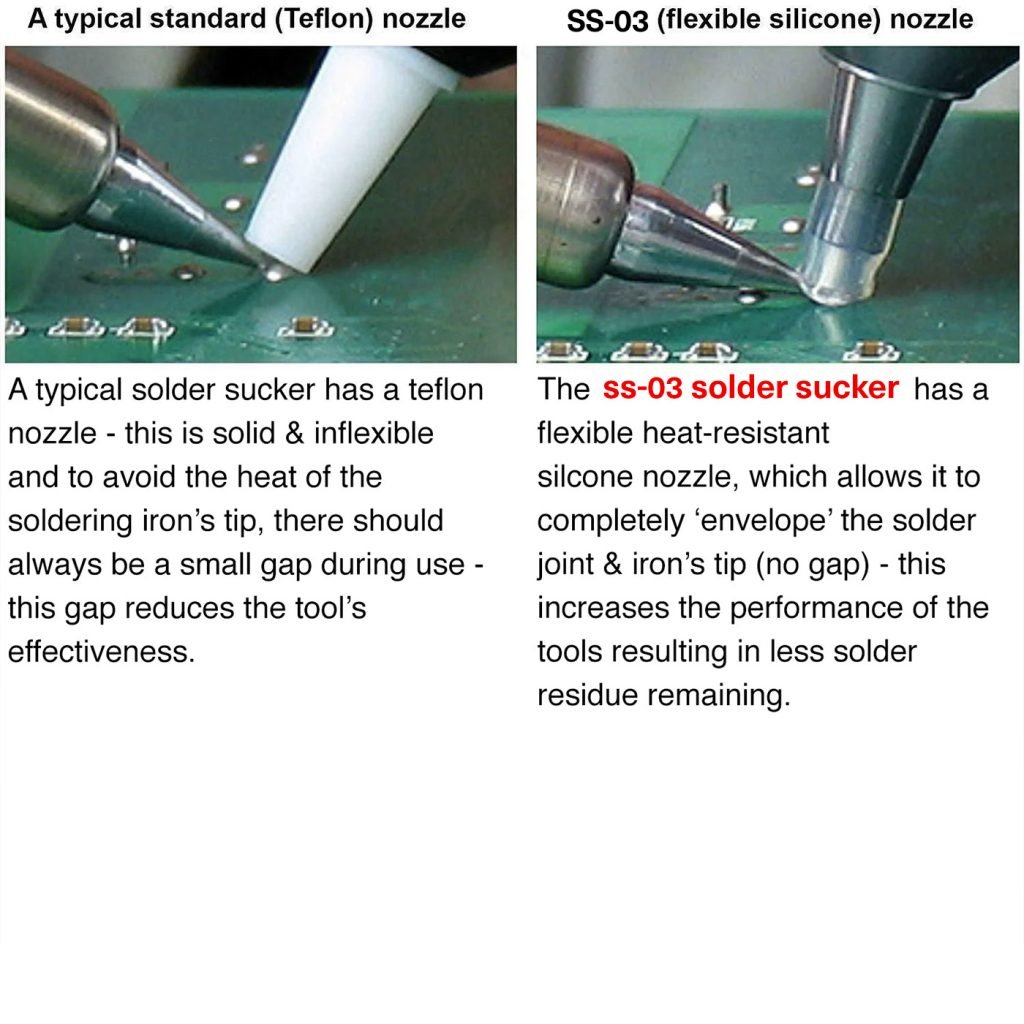

The Engineer SS-03 Solder Sucker is at the cutting edge of solder removal technology. The flexible heat resistant silicone tip allows the nozzle to come into direct contact with the soldering iron without damage, and allows the nozzle to ‘envelope’ the solder joint. This dramatically improves suction, and leaves less solder residue remaining.

Unlike the SS-03, traditional solder suckers have a solid nozzle. In order to avoid heat damage these hard and inflexible nozzles require the user to leave a small gap between the nozzle and soldering tip – This gap reduces the tool’s effectiveness.

The SS-03’s plunger is within easy reach of the thumb, making it ideal for one-hand operation in continuous work.

The self-cleaning shaft prevents clogging, and the unit is easily disassembled for quick maintenance.

Nozzles are easily replaced: The SS-03 comes with supplied with two silicone tubes which can be cut down for use as replacement nozzles.

Replacement packs of 2 x 50mm length silicone tubes are also available HERE.

- Innovative flexible silicone nozzle tip allows closer placement to the soldering iron tip (resulting in better suction & solder removal)

- Withstands direct contact with soldering iron tip (350C max)

- Compact design allows easy one handed operation

- Highest quality construction & components used

- Easily disassembled for quick maintenance

- Supplied with two silicone tubes – 1.5mm(ID) x 3.0mm(OD) x 50mm(L) and also 2.0mm(ID) x 3.0mm(OD) x 50mm(L) – these can be cut down for use as replacement nozzles.

- Made in Japan (ROHS compliant)

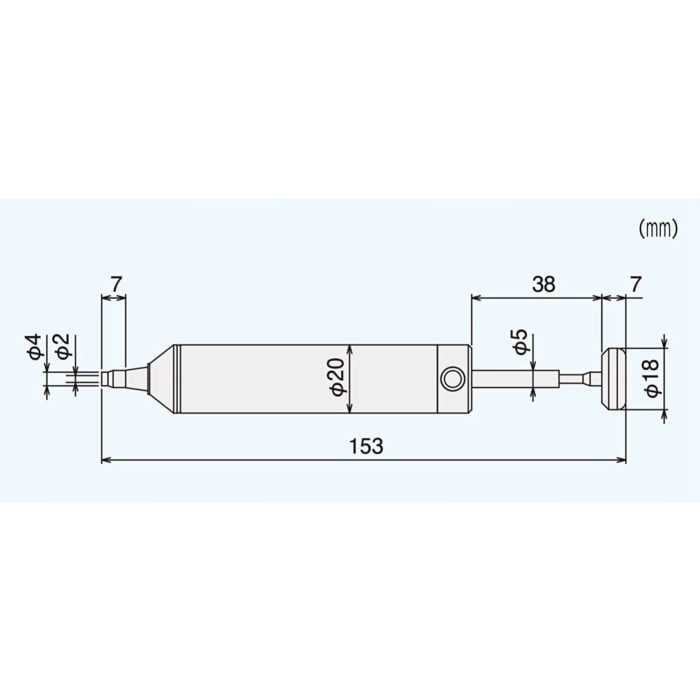

Cylinder Capacity: 9cc

Size: 20x153mm

Weight: 52g

Made in Japan

Clean your solder sucker often!

We advise cleaning carefully after each session of use. Remove the silicon tip and push the plunger all the way through to clean the metal tip. After multiple uses also unscrew the conical end piece and remove all residue inside the chamber. Careful care of this precision tool will ensure a long life.